GENERAL CHARACTERISTICS

Heat Exchangers are the best solution to heat fluids flowing in forced convection. Electrical Heat Exchangers operate in the same way as fluid/fluid heat exchanger but the hot side consists of armoured electrical heaters in direct contact with the fluid to be heated. An optimum heat exchange is obtained employing appropriate baffles whose design is tailored to exploit at best the heat released by the electrical resistances.

APPLICATIONS

- Heating of moulds or blocks containing fluid circulating loops

- Oil separation and filtration

- Combustible oils pre-heating hot transfer of heavy oils

- Hot water supply to cleaning and rinsing tanks

- Anti-frost protection

- Technical and process gases heating

- Additional heating unit (back-up of the primary one)

TECHNICAL DATA

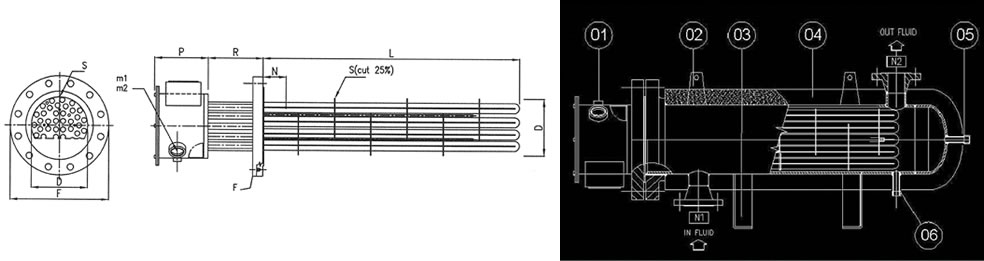

Heat Exchanger can be manufactured with carbon steel or stainless steel shell:

![]() 1 Power supply cable inlet

1 Power supply cable inlet

![]() 2 Eyelets for heat exchanger hoisting or moving

2 Eyelets for heat exchanger hoisting or moving

![]() 3 Supporting frames for mechanical fixation

3 Supporting frames for mechanical fixation

![]() 4 Thermal insulation (if requested)

4 Thermal insulation (if requested)

![]() 5-6 Drain connections

5-6 Drain connections